12345678910111213141516171819202122232425262728293031

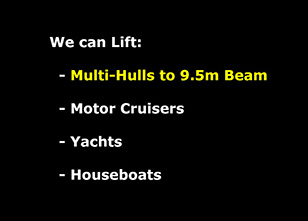

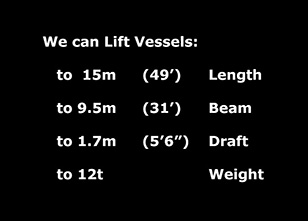

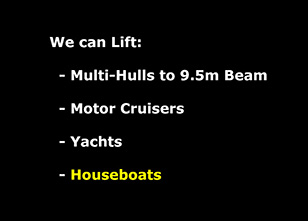

Lifting / Antifouling

We encourage you to either call us or e-mail us for bookings and enquiries.

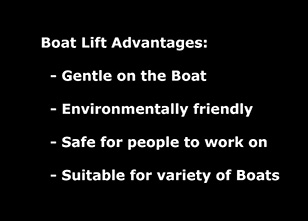

In a typical year we will service and antifoul 2 to 3 hundreds of vessels ranging from runabouts to the larger sail and motor yachts. Our high level of repeat business gives us the ideal opportunity to undertake continual evaluation of our products and performance. Our experience has led us to the point where we feel we can offer the best possible advice to our antifoul customers.